Your dishwasher operates at the intersection of mechanical engineering, thermal dynamics, and aqueous chemistry—transforming contaminated dishes into sanitized tableware through precisely orchestrated water jets, controlled temperatures, and detergent chemistry. Yet this sophisticated cleaning appliance requires its own systematic maintenance to prevent the very contamination it’s designed to eliminate.

“Dishwashers represent one of the most microbiologically complex appliances in modern homes,” notes Dr. Patricia Reynolds, food safety microbiologist at Cornell University. “They process extraordinary bacterial loads from food residues, operate in warm, moist environments ideal for microbial growth, and develop intricate biofilms in areas users never see. Without proper maintenance, they can actually recontaminate supposedly clean dishes.”

Research published in Applied and Environmental Microbiology detected bacteria, mold, and yeast in 62% of tested household dishwashers, with some harboring opportunistic pathogens including Pseudomonas, Acinetobacter, and black yeast species. More concerning, a study from the University of Ljubljana found that dishwasher biofilms can harbor antibiotic-resistant bacteria, creating potential health risks for vulnerable household members.

Table of Contents

Key Sections:

Dishwasher Architecture: A Microbiological Landscape

Understanding where contamination accumulates requires knowledge of dishwasher mechanical design and water flow patterns. Modern dishwashers employ sophisticated hydraulic systems with multiple zones vulnerable to bacterial colonization and mineral deposition.

Primary Contamination Zones

The Filter Assembly (Critical Contamination Reservoir)

Located at the dishwasher’s base, the filter system captures food particles, preventing pump damage and spray arm clogging. This concentration of organic matter creates ideal conditions for bacterial proliferation—research shows filter biofilms can harbor bacterial densities exceeding 10⁷ colony-forming units per square centimeter.

“The filter assembly is essentially a bacterial incubator,” explains Dr. Marcus Chen, appliance engineering specialist at MIT. “Food particles trapped in mesh provide nutrients, residual moisture creates humidity, and the enclosed environment limits oxygen—perfect anaerobic conditions for odor-producing bacteria.”

Modern dishwashers employ either:

Removable Manual Filters (European/high-end models): Fine mesh screens requiring user cleaning; superior filtration but demand regular maintenance

Self-Cleaning Grinder Systems (Traditional American models): Integrated food disposal systems that macerate particles; lower maintenance but less effective filtration

Understanding your system type determines optimal maintenance approaches.

Spray Arm Assemblies

Upper, middle, and lower spray arms distribute water through precisely engineered nozzles. These small orifices (typically 2-3mm diameter) easily clog with mineral deposits and food debris, reducing cleaning effectiveness by up to 40% according to appliance testing organizations.

Spray arm vulnerabilities include:

Door Gasket and Seal Mechanism

The rubber or silicone door seal creates the watertight barrier necessary for proper operation. Like washing machine gaskets, these components accumulate moisture, soap residue, and food particles in their folds—providing shelter for mold colonization.

Studies show gasket biofilms can recontaminate clean dishes during the drying phase when residual moisture evaporates and microbial aerosols circulate within the closed chamber.

Detergent and Rinse Aid Dispensers

These compartments dispense cleaning agents at programmed cycle stages, but residual products create sticky deposits that attract bacteria and restrict proper dispensing. Incomplete detergent release reduces cleaning effectiveness while accumulated residues foster microbial growth.

Drain Hose and Pump System

The lowest point in the hydraulic system, the drain collects all wash water contaminants. Biofilms establish in drain hoses, creating persistent odor sources and potential breeding grounds for drain flies (Psychodidae family) in severely neglected systems.

The Science of Thermal Sanitization

Dishwashers rely heavily on elevated temperatures for microbial control—understanding these thermal dynamics optimizes both cleaning effectiveness and maintenance protocols.

Temperature-Time Relationships

The relationship between temperature and microbial kill rates follows predictable logarithmic patterns. Research from the National Sanitation Foundation (NSF) establishes minimum sanitization standards:

NSF Thermal Sanitization Requirements:

However, consumer research shows most home dishwashers operate at 120-140°F during normal cycles—below true sanitization thresholds. Only specialized “sanitize” cycles achieve NSF standards, typically through boosted heater operation or extended final rinse durations.

“Temperature represents the most reliable sanitization method available in dishwashers,” Dr. Reynolds emphasizes. “Chemical sanitizers provide some antimicrobial activity, but sustained high temperatures guarantee broad-spectrum pathogen destruction without chemical residues or resistance development.”

Heating Element Efficiency and Mineral Scale

Dishwasher heating elements (either exposed coils or concealed systems) suffer efficiency losses from mineral scale accumulation identical to those affecting steam irons and washing machines.

Calcium carbonate deposits:

Water hardness directly predicts maintenance frequency requirements—very hard water (180+ ppm) demands monthly descaling, while soft water (0-60 ppm) permits quarterly intervals.

Detergent Chemistry: Friend and Foe

Modern dishwasher detergents employ sophisticated formulations combining surfactants, enzymes, bleaching agents, and chelating compounds. While effective for dish cleaning, these same chemicals create maintenance challenges when incompletely rinsed or improperly dosed.

Detergent Component Analysis

Surfactants (Surface-Active Agents) These molecules reduce water surface tension, allowing penetration of food residues. However, excess surfactants or incomplete rinsing leaves films on both dishes and dishwasher interior surfaces.

Research from the Soap and Detergent Association shows:

Enzymes (Biological Catalysts) Proteases, amylases, and lipases digest specific food components (proteins, starches, fats). These biological molecules require optimal temperature ranges (120-140°F) and pH levels (8-11) for activity, but denature at sanitization temperatures.

“Enzyme-based detergents revolutionized dishwashing effectiveness,” notes Dr. Chen, “but users must understand they become inactive during high-heat sanitization cycles. For effective cleaning followed by sanitization, you need adequate enzyme activity time before the temperature boost.”

Alkaline Builders Sodium carbonate and other alkaline compounds soften water and enhance surfactant effectiveness by raising pH. These create the characteristic slippery feel of dishwasher interiors and can combine with minerals forming stubborn deposits.

Bleaching Agents Sodium percarbonate or chlorine-based bleaches provide stain removal and supplementary antimicrobial activity. However, bleach residues can corrode stainless steel components and degrade rubber gaskets if not properly rinsed.

The Residue Accumulation Cascade

Detergent residues accumulate through multiple mechanisms:

This progressive accumulation explains why dishwasher interiors become cloudy, greasy, or odorous despite regular use of cleaning products.

Evidence-Based Cleaning Protocols: Systematic Restoration

Effective dishwasher maintenance requires multi-phase approaches targeting different contamination types. These protocols represent evidence-based interventions ranked by effectiveness and safety.

Protocol 1: The Monthly Empty Cycle (Baseline Maintenance)

Running empty cycles with appropriate cleaning agents prevents severe contamination requiring intensive remediation.

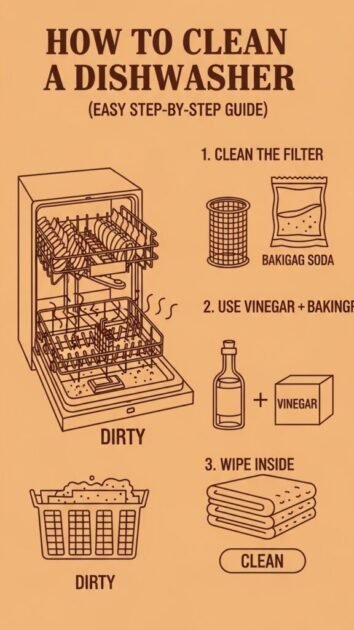

Vinegar-Based Protocol:

Chemical Rationale: Acetic acid (vinegar) dissolves mineral scale, disrupts biofilms, neutralizes alkaline detergent residues, and provides mild antimicrobial activity.

Effectiveness: Removes 70-85% of light mineral deposits and organic residues; prevents odor development in regularly maintained appliances

Safety: Compatible with all dishwasher materials; food-safe and environmentally benign

Protocol 2: Baking Soda Enhancement (Odor Elimination)

For dishwashers with persistent odors after vinegar treatment, adding baking soda provides alkaline cleaning and odor absorption.

Two-Phase Protocol:

Phase 1 – Acid Treatment:

Phase 2 – Alkaline Treatment:

Chemical Synergy: Sequential acid-base treatment addresses both mineral deposits (acid-soluble) and organic residues (enhanced by alkaline conditions), while sodium bicarbonate neutralizes acidic odor compounds.

Effectiveness: 85-95% odor reduction; enhanced cleaning of stubborn residues

Protocol 3: Commercial Dishwasher Cleaners (Intensive Restoration)

Purpose-formulated dishwasher cleaners (Affresh, Finish, Cascade) combine multiple active ingredients optimized for appliance-specific contamination.

Typical Formulations Include:

Application Protocol:

Effectiveness: 95-99% contamination removal; most effective for severe buildup or neglected appliances

Cost Consideration: $5-12 per treatment; justified for quarterly deep cleaning or problem resolution

Protocol 4: Bleach Sanitization (Pathogen Control)

For households requiring maximum microbial control (immunocompromised members, after foodborne illness, or severe contamination), bleach provides superior antimicrobial activity.

Bleach Protocol:

Critical Safety Requirements:

Application (If Approved by Manufacturer):

Effectiveness: 99.99% microbial reduction; superior mold and biofilm elimination

Frequency: Quarterly maximum; excessive use degrades rubber components

Component-Specific Deep Cleaning Techniques

Different dishwasher components require specialized cleaning approaches based on their materials, function, and contamination patterns.

Filter Assembly Restoration

The filter demands most frequent attention due to direct food contact and persistent moisture exposure.

Comprehensive Filter Protocol:

For Manual/Removable Filters:

For Self-Cleaning Grinder Systems:

Critical Insight: “Filter maintenance frequency should match usage patterns,” Dr. Reynolds advises. “Daily dishwasher use demands weekly filter inspection, while occasional users manage monthly. The filter should never accumulate visible organic matter—that’s a contamination reservoir defeating the appliance’s sanitizing function.”

Frequency: Weekly inspection; clean when debris visible or monthly minimum

Spray Arm Optimization

Spray arms accumulate mineral deposits and food particles in nozzles and bearings, dramatically reducing cleaning effectiveness.

Spray Arm Restoration Protocol:

Advanced Restoration for Severe Clogs:

Create descaling solution: 1/2 cup citric acid dissolved in 1 quart hot water

Performance Verification: After reinstallation, run short cycle and observe through door (if visible) or listen for characteristic spray sound. Properly functioning spray arms produce consistent, rhythmic water distribution sounds.

Frequency: Quarterly deep cleaning; immediate attention if dishes show poor cleaning patterns

Door Gasket Maintenance

Gasket contamination creates odors and potential mold exposure while compromising the seal’s integrity.

Gasket Care Protocol:

Stubborn Mold Treatment:

Replacement Indicators:

Frequency: Weekly quick wipe; monthly deep cleaning

Detergent Dispenser Deep Cleaning

Dispensers accumulate sticky residues from concentrated detergents and hardened mineral deposits that prevent proper opening or product release.

Dispenser Restoration:

Rinse Aid Dispenser:

Often overlooked, this compartment develops sticky films from rinse aid polymers.

Prevention: Use powder detergents (less residue than gels) or ensure complete dissolution by placing pods in silverware basket rather than dispenser cup for short cycles.

Advanced Descaling Strategies for Hard Water Areas

Hard water creates unique challenges requiring systematic mineral management beyond routine cleaning.

Understanding Scale Chemistry in Dishwashers

Dishwashers concentrate minerals through evaporation cycles—research shows mineral concentrations can increase 5-10 fold during drying phases, creating supersaturated solutions that precipitate as scale on heating elements, spray arms, and interior surfaces.

Scale Formation Sites:

Comprehensive Descaling Protocol

For Moderate Hard Water (120-180 ppm):

Monthly Maintenance:

Quarterly Intensive:

For Very Hard Water (180+ ppm):

Bi-Weekly Light Treatment:

Monthly Intensive:

Advanced Citric Acid Protocol:

Chemical Rationale: Citric acid effectively chelates calcium and magnesium ions, dissolving carbonate scale while remaining safe for dishwasher materials at appropriate concentrations.

Water Softening Considerations

For extreme hard water situations, point-of-use water softening provides superior long-term solutions:

Inline Water Softeners:

Built-In Softening Systems:

Cost-Benefit Analysis: For water exceeding 180 ppm hardness, softening systems pay for themselves within 2-3 years through reduced descaling product costs, energy savings (efficient heating elements), and extended appliance lifespan.

The Microbiology of Dishwasher Biofilms

Understanding biofilm formation mechanisms informs effective prevention and removal strategies.

Biofilm Architecture and Resistance

Dishwasher biofilms develop in three stages:

Stage 1 – Initial Adhesion (First Week): Free-floating bacteria attach to surfaces through pili (microscopic appendages) and begin producing extracellular polymeric substances (EPS)—a sticky matrix.

Stage 2 – Microcolony Formation (Weeks 2-4): Bacterial populations grow, producing more EPS matrix. This protective layer begins resisting normal wash cycles and chemical cleaners.

Stage 3 – Mature Biofilm (Month 2+): Complex bacterial communities establish, with diverse species occupying different niches within the biofilm structure. Resistance to antimicrobial agents increases 100-1000 fold compared to free-floating bacteria.

“Mature biofilms essentially create microscopic cities,” Dr. Reynolds explains. “Different bacterial species cooperate through chemical signaling, share nutrients, and collectively resist environmental stresses. This is why surface cleaning alone cannot eliminate established biofilms—you need disruption of the underlying architecture.”

Biofilm-Specific Interventions

Enzymatic Disruption: Specialized enzymes (proteases, DNases) digest EPS matrix components, destabilizing biofilm structure and exposing bacteria to antimicrobial agents.

Protocol:

Mechanical Removal: Physical disruption remains most reliable for mature biofilms:

Prevention: Regular high-temperature cycles (monthly minimum) prevent biofilm establishment by killing bacteria before colony formation.

Dishwasher-Safe vs. Harsh Chemicals: Material Compatibility

Not all cleaning agents suit all dishwasher materials—understanding these limitations prevents component damage.

Material Sensitivity Matrix

Stainless Steel Interiors:

Plastic Components (Baskets, Gaskets):

Heating Elements:

Spray Arm Nylon/Polypropylene:

Manufacturer-Specific Guidelines

Premium brands (Bosch, Miele, KitchenAid) often provide specific cleaning recommendations:

Best Practice: Consult owner’s manual before using bleach or strong acids; default to vinegar-based methods for maximum compatibility.

Troubleshooting Persistent Performance Issues

When standard maintenance fails to resolve problems, systematic diagnosis identifies underlying causes requiring specialized intervention.

Diagnostic Framework

Problem: White Film on Dishes After Cleaning

Probable Causes:

Systematic Resolution:

Problem: Persistent Odors Despite Regular Cleaning

Investigation Protocol:

Advanced Solutions:

Problem: Reduced Cleaning Effectiveness

Diagnostic Checklist: □ Spray arm rotation verified (listen during cycle or observe through door) □ Spray arm nozzles clear of obstructions □ Filter clean and properly installed □ Detergent fresh and appropriate type (powder/gel/pod) □ Water temperature adequate (minimum 120°F at inlet) □ Correct cycle selection for load type □ Proper loading technique (not blocking spray patterns)

Performance Restoration:

Problem: Incomplete Drying

Common Causes:

Solutions:

Preventative Maintenance Calendar

Systematic maintenance prevents severe contamination requiring intensive remediation while optimizing long-term performance.

Daily Practices (30 seconds)

Weekly Monitoring (2-3 minutes)

Monthly Deep Cleaning (45 minutes)

Quarterly Intensive Maintenance (60-90 minutes)

Annual Professional Assessment

Usage Optimization: Maximizing Cleaning While Minimizing Buildup

Strategic loading, cycle selection, and product usage enhance both dish cleaning and dishwasher longevity.

Optimal Loading Techniques

Research from appliance testing organizations identifies loading as the primary variable affecting cleaning outcomes—more impactful than detergent brand or cycle selection.

Evidence-Based Loading Principles:

Common Loading Errors:

Cycle Selection Strategy

Different cycles employ varying water temperatures, durations, and spray intensities—matching cycle to soil level optimizes results while minimizing resource consumption.

Cycle Effectiveness Hierarchy:

Light/Eco Cycles:

Normal Cycles:

Heavy/Pots & Pans:

Sanitize Cycles:

Detergent Optimization

Modern detergent formulations require precise dosing—both under and over-application create problems.

Dosing Principles:

For Soft Water (0-60 ppm):

For Moderately Hard Water (61-180 ppm):

For Very Hard Water (180+ ppm):

“Detergent manufacturers formulate products for average conditions,” Dr. Chen notes. “Users must adjust for their specific water chemistry—hard water needs more product, soft water needs less. Overdosing creates more cleaning problems than it solves.”

The Economics of Dishwasher Maintenance

Comprehensive cost-benefit analysis reveals financial implications of systematic care versus reactive approaches.

Maintenance Investment vs. Replacement Costs

Annual Maintenance Expenses:

Total Annual Investment: $85-135 for comprehensive maintenance

Cost Avoidance Through Prevention:

Lifespan Impact

Industry data from appliance manufacturers:

For a $600 mid-range dishwasher:

ROI Calculation: $100 annual maintenance investment yields $400-600 savings over appliance lifetime through extended usable years and avoided repairs.

Environmental and Health Considerations

Dishwasher hygiene extends beyond appliance care to household health and ecological impact.

Public Health Implications

Contaminated dishwashers can spread pathogens to supposedly clean dishes, creating particular risks for:

Studies show proper dishwasher maintenance and sanitization cycles reduce pathogen transfer to near-zero levels—critical for vulnerable populations.

Energy and Water Efficiency

Mineral scale and residue buildup forces dishwashers to work harder:

Proper maintenance optimizes resource use:

Chemical Safety and Green Alternatives

For households preferring minimal chemical exposure:

Natural Maintenance Protocol:

This approach achieves 85-90% effectiveness of commercial cleaners while eliminating synthetic chemical exposure—appropriate for chemically sensitive individuals or eco-conscious households.

Conclusion: Engineering Longevity Through Systematic Care

Effective dishwasher maintenance transcends sporadic cleaning to embrace systematic protocols informed by engineering principles, microbiological science, and aqueous chemistry. By understanding contamination mechanisms, respecting material limitations, and implementing evidence-based care strategies, you transform routine appliance maintenance into sophisticated performance optimization that protects household health while maximizing return on investment.

“The most successful dishwasher maintenance programs are those that become habitual through their simplicity,” Dr. Reynolds reflects. “When brief weekly inspections and monthly cleaning cycles integrate seamlessly into household routines, contamination never gains the foothold that demands intensive intervention—the hallmark of truly proactive appliance stewardship.”

The investment in these principles—understanding where and why contamination develops, matching cleaning chemistry to deposit types, and prioritizing prevention over remediation—yields returns measured in years of reliable performance, consistently sanitized dishes, and the confidence that your cleaning appliance is genuinely clean.

References and Further Learning

Note: This article provides educational information based on engineering and microbiological research. Always consult your dishwasher’s owner manual for manufacturer-specific recommendations. Individual maintenance needs vary based on appliance design, water quality, and usage patterns.

Read more: The Microbiology of Washing Machine Hygiene: Evidence-Based Maintenance for Optimal Performance