Your washing machine harbors a complex microbial ecosystem that most users never consider—until mysterious odors, visible mold growth, or dingy laundry signal a serious contamination problem. Understanding the intersection of microbiology, chemistry, and mechanical engineering reveals why modern washing machines require active maintenance despite their cleaning function, and how targeted interventions restore both hygiene and performance.

“Washing machines represent a fascinating paradox,” notes Dr. Lisa Martinez, microbiologist at the University of Arizona. “We design them to clean our belongings, yet they create ideal conditions for bacterial and fungal proliferation—warm, moist environments with organic matter and limited air circulation. Without proper maintenance, they become contamination sources rather than cleaning tools.”

Research published in Applied and Environmental Microbiology identified over 60 different microbial species in residential washing machines, including potential pathogens like Pseudomonas, Staphylococcus, and various mold species. More concerningly, a study from the University of Arizona found that 60% of tested washing machines transferred bacteria to supposedly clean laundry, with some items showing higher bacterial loads after washing than before.

Table of Contents

Key Sections:

The Microbial Geography of Washing Machines

Modern washing machines contain multiple ecological niches where bacteria, mold, and biofilms establish persistent colonies. Understanding these contamination zones allows for targeted cleaning interventions that address root causes rather than symptoms.

Primary Contamination Sites

The Rubber Door Gasket (Front-Load Machines)

The folded rubber seal surrounding front-load washer doors creates a dark, perpetually damp crevice—essentially a microbial incubator. Research from the Household and Personal Products Industry (HAPPI) shows gasket biofilms can harbor bacterial concentrations exceeding 1 million colony-forming units (CFU) per square centimeter.

“Gasket design represents a fundamental tension between water containment and microbial control,” explains Dr. James Chen, appliance engineering researcher at Purdue University. “The very folds that prevent leakage also trap moisture and organic matter, creating anaerobic pockets where odor-producing bacteria thrive unchecked.”

Common gasket colonizers include:

The Detergent Drawer and Dispenser

Detergent dispensers accumulate residue from concentrated cleaning products, fabric softeners, and hard water minerals. This nutrient-rich environment supports bacterial and mold growth, with colonies visible as pink, black, or gray slimy deposits.

Microbiological analysis reveals:

The Drum Interior and Door Glass

While appearing clean, drum surfaces develop invisible biofilms—complex bacterial communities embedded in self-produced polymer matrices. These films resist conventional washing cycles and serve as persistent contamination sources.

“Biofilm architecture is remarkably sophisticated,” Dr. Martinez notes. “Bacterial cells communicate chemically, coordinate behavior, and create protective barriers up to 1000 times more resistant to antimicrobial agents than free-floating cells. Surface wiping alone cannot penetrate these structures.”

Drain Pump and Filter System

The washing machine’s lowest point collects lint, coins, fabric debris, and residual water—creating a concentrated contamination reservoir. Studies show drain systems harbor the highest microbial diversity and concentration of any machine component, with anaerobic bacteria producing sulfurous odors characteristic of neglected machines.

Inlet Hoses and Water Supply Lines

Though less obvious, inlet hoses accumulate biofilm on internal surfaces, particularly in warm climates or homes with well water. These colonies can introduce bacteria with each fill cycle, recontaminating freshly cleaned drums.

Front-Load vs. Top-Load: Design-Driven Contamination Patterns

Washing machine architecture fundamentally influences microbial colonization patterns and required maintenance approaches. Understanding these design-specific vulnerabilities optimizes cleaning effectiveness.

Front-Load Machine Microbiology

Structural Vulnerabilities:

Front-load washers’ horizontal drum orientation and rubber gasket design create inherent contamination risks. The gasket’s complex folded geometry traps water after cycles, preventing complete drying between uses. Additionally, front-loaders’ water-efficient design (using 40-60% less water than traditional top-loaders) means lower water volumes may not fully rinse away residue and bacteria.

European research comparing machine types found front-loaders harbor 3-5 times higher bacterial concentrations in gasket areas compared to top-load equivalents, though overall drum cleanliness remains comparable with proper maintenance.

Odor Generation Mechanisms:

The characteristic musty smell of contaminated front-loaders results from volatile organic compounds (VOCs) produced by anaerobic bacteria in oxygen-depleted gasket folds. These bacteria metabolize trapped organic matter (skin cells, fabric fibers, detergent residues) into malodorous sulfur and nitrogen compounds.

Optimal Maintenance Focus:

Top-Load Machine Dynamics

Design Advantages:

Traditional top-load washers’ vertical orientation and absence of front gaskets eliminate the primary contamination reservoir found in front-loaders. Water drains completely from the drum, and the open-top design facilitates faster drying.

However, top-loaders face their own challenges:

High-Efficiency (HE) Top-Load Complications:

Modern HE top-loaders without agitators use impeller plates and reduced water volumes, creating new contamination patterns:

“HE washers represent a compromise between water efficiency and thorough rinsing,” Dr. Chen observes. “Users must adjust cleaning product amounts and maintenance frequency to compensate for reduced water volumes.”

The Chemistry of Detergent Residue and Scale Formation

Modern laundry products contribute to washing machine contamination through complex chemical interactions. Understanding these processes informs cleaning product selection and maintenance protocols.

Surfactant Accumulation Dynamics

Laundry detergents contain surfactants (surface-active agents) that reduce water’s surface tension, allowing penetration of fabric fibers. However, these same compounds can polymerize and adhere to machine surfaces, especially in cold-water washes where dissolution remains incomplete.

Research from the Soap and Detergent Association shows:

Residue-Microbe Interactions:

Detergent residues serve as nutrient sources for bacterial growth, creating a self-reinforcing contamination cycle. Surfactant films also protect bacteria from subsequent wash cycles, essentially providing shelter alongside food.

Fabric Softener Complications

Fabric softeners and dryer sheets deposit cationic surfactants and silicones that accumulate on machine surfaces, creating particularly stubborn residues. These compounds:

“Fabric softener residue represents some of the most challenging contamination to remove,” Dr. Martinez notes. “The very properties that make fabrics feel soft—hydrophobic films and conditioning agents—also make these residues resist water-based cleaning methods.”

Hard Water Mineral Scaling

Similar to steam irons, washing machines accumulate calcium and magnesium carbonate deposits in hard water areas. These mineral scales:

The interaction between minerals and organic residues creates particularly stubborn hybrid deposits requiring both acidic descaling agents and surfactant-based cleaners.

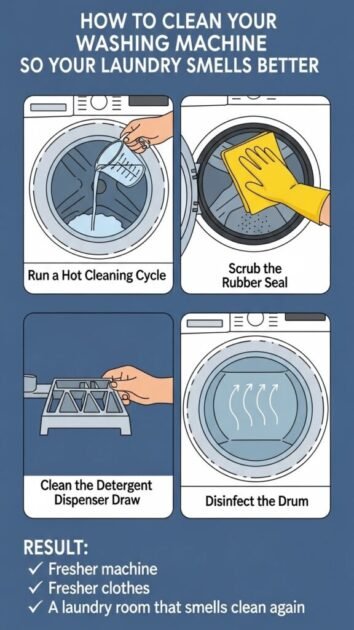

Evidence-Based Cleaning Protocols: Comprehensive Machine Restoration

Effective washing machine maintenance requires multi-phase approaches addressing different contamination types. The following protocols represent evidence-based interventions ranked by effectiveness and material safety.

Protocol 1: High-Temperature Sanitization Cycle (Monthly Baseline)

Heat represents the most reliable microbial control method. Research published in the International Journal of Food Microbiology demonstrates that sustained temperatures above 140°F (60°C) achieve 99.99% bacterial reduction within 10 minutes.

Optimal Implementation:

Effectiveness: Eliminates 95-99% of microorganisms; removes 70-85% of light to moderate residue buildup

Limitations: May not fully remove hardened mineral-biofilm composites in severely neglected machines

Protocol 2: Bleach Treatment (Quarterly Deep Sanitization)

Sodium hypochlorite (chlorine bleach) provides superior antimicrobial activity across broad spectrum of bacteria, viruses, and mold. CDC guidelines for healthcare laundry specify bleach concentrations for pathogen control, principles applicable to home machines.

Professional-Grade Protocol:

Effectiveness: 99.99% microbial kill rate; superior mold removal

Cautions:

Protocol 3: Enzymatic Biofilm Disruption (Advanced Restoration)

For persistent odors despite regular cleaning, enzymatic cleaners specifically designed for biofilm disruption offer targeted effectiveness. These products contain proteases, lipases, and cellulases that digest the organic polymer matrix protecting bacterial colonies.

Biofilm-Specific Approach:

Effectiveness: Superior biofilm penetration and removal; 85-95% odor elimination in single treatment

Cost Consideration: $5-15 per treatment; justified for severe contamination

Protocol 4: Citric Acid Descaling (Hard Water Maintenance)

For machines in hard water areas, periodic descaling prevents mineral accumulation that facilitates bacterial colonization and reduces heating efficiency.

Descaling Protocol:

Alternative: Use 2 cups white vinegar for milder descaling (less effective but more readily available)

Frequency: Monthly in very hard water (180+ ppm); quarterly in moderately hard water (120-180 ppm)

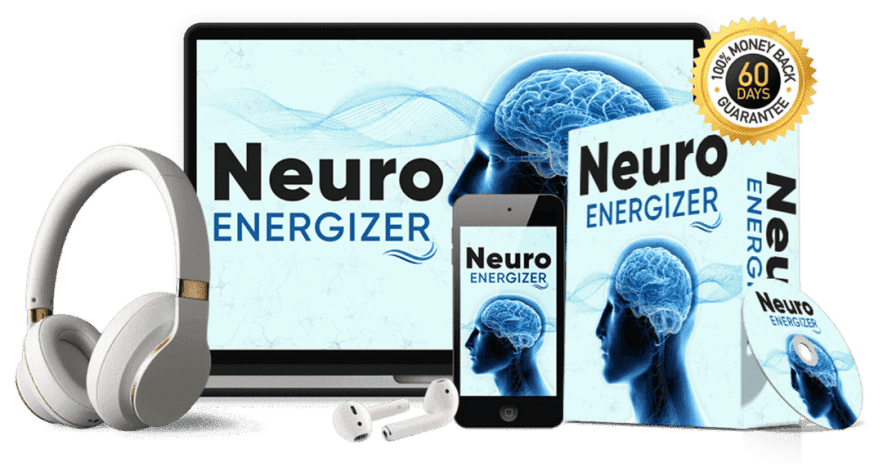

Component-Specific Deep Cleaning Techniques

Different machine components require specialized cleaning approaches based on material composition and contamination patterns.

Gasket Deep Cleaning (Front-Load Machines)

The rubber gasket demands meticulous attention due to its complex geometry and vulnerability to mold colonization.

Comprehensive Gasket Protocol:

Stubborn Mold Removal:

For persistent black mold spots:

Prevention: Wipe gasket after every wash; monthly deep cleaning prevents colony establishment

Detergent Drawer Restoration

Dispensers accumulate layered deposits from liquid detergents, powders, and fabric softeners, often becoming completely clogged in neglected machines.

Complete Dispenser Cleaning:

Frequency: Monthly visual inspection; clean every 2-3 months or when flow appears restricted

Drain Pump Filter Maintenance

The pump filter (found in front-lower panel of most front-loaders; access varies in top-loaders) collects debris preventing pump damage, but requires regular cleaning to prevent odors and drainage problems.

Filter Cleaning Protocol:

Warning Signs Requiring Filter Cleaning:

Frequency: Every 1-3 months depending on usage; immediately if drainage issues appear

Drum and Door Glass

While drum surfaces receive some cleaning during regular wash cycles, targeted maintenance enhances results.

Drum Enhancement Protocol:

Usage Patterns That Minimize Contamination

Washing machine hygiene extends beyond periodic cleaning to encompass daily habits that prevent microbial colonization and residue accumulation.

Post-Wash Protocols

Immediate Actions After Each Use:

“The single most impactful habit change for front-load washer owners is leaving the door open between uses,” Dr. Chen emphasizes. “This simple behavior reduces mold colonization by 80% compared to immediately closing the door—essentially eliminating the most common contamination driver.”

Detergent Usage Optimization

Modern HE machines require significantly less detergent than users typically apply—excess product creates more problems than benefits.

Evidence-Based Detergent Practices:

Research from consumer testing organizations shows that using twice the recommended detergent amount actually decreases cleaning effectiveness due to incomplete rinsing and residue attraction of dirt.

Water Temperature Strategy

While hot water sanitizes effectively, strategic temperature selection balances hygiene and efficiency.

Temperature Guidelines:

Best Practice: Use cold for regular laundry, but run one hot cycle monthly (empty cleaning cycle or towels/bedding) to prevent biofilm establishment

Load Size Optimization

Overloading reduces cleaning effectiveness and increases residue accumulation; underloading wastes resources and may not properly activate HE sensors.

Optimal Loading:

The Science of Odor Production and Elimination

Understanding odor chemistry informs targeted interventions beyond generic cleaning.

Bacterial Metabolism and Volatile Organic Compounds

The musty smell characteristic of contaminated washing machines results from bacterial metabolic byproducts. Different bacterial species produce distinct compounds:

Research from the Building and Environment journal shows these compounds adsorb onto machine surfaces and fabrics, persisting even after bacteria elimination unless specifically targeted.

Odor Elimination vs. Masking

Many commercial cleaners simply mask odors with fragrances rather than eliminating source bacteria. True odor resolution requires:

Activated Charcoal Approach:

For persistent odors after microbial cleaning:

Troubleshooting Persistent Performance Issues

When standard cleaning protocols fail to restore functionality, systematic diagnosis identifies underlying problems requiring specialized intervention.

Diagnostic Framework

Problem: Persistent Musty Odors After Multiple Cleanings

Probable Causes:

Advanced Solutions:

Problem: Reduced Cleaning Effectiveness

Investigation Protocol:

Problem: Visible Mold Growth Despite Regular Maintenance

Underlying Issues:

Comprehensive Response:

Preventative Maintenance Calendar

Systematic maintenance prevents severe contamination requiring intensive remediation.

Daily Practices (30 seconds)

Weekly Monitoring (2 minutes)

Monthly Deep Cleaning (45-60 minutes)

Quarterly Intensive Maintenance (90 minutes)

Annual Professional Assessment

Machine-Specific Considerations: Manufacturer Guidelines

Different manufacturers design machines with varying materials and mechanisms requiring tailored approaches.

European-Design Front-Loaders (Bosch, Miele, Electrolux)

These machines typically feature:

Maintenance Advantages: Built-in sanitization cycles; follow manufacturer cleaning cycles monthly

American-Design Machines (Whirlpool, Maytag, GE)

Typically feature:

Caution: Verify chemical compatibility before using bleach or strong acids

Compact and Portable Models

Smaller machines face unique challenges:

Enhanced Protocol: More frequent manual cleaning compensates for limited built-in sanitization features

The Economics of Washing Machine Maintenance

Comprehensive cost-benefit analysis reveals financial implications of maintenance investment.

Expense Analysis

Maintenance Costs (Annual):

Total Annual Investment: $50-75 for comprehensive maintenance

Cost Avoidance:

Appliance Lifespan Impact

Industry data from appliance manufacturers shows:

For a $800 mid-range machine:

“The return on investment for washing machine maintenance is exceptional,” Dr. Chen notes. “A $50 annual investment can extend appliance lifespan 40-50%, creating effective savings of thousands of dollars over a household’s washing machine lifetime.”

Environmental and Health Implications

Washing machine hygiene extends beyond appliance care to household health and environmental stewardship.

Indoor Air Quality Considerations

Mold-contaminated washing machines release spores into laundry areas, affecting indoor air quality. Studies published in Environmental Health Perspectives link household mold exposure to:

Proper machine maintenance eliminates this contamination source, improving overall home air quality.

Laundry Hygiene and Cross-Contamination

Research from the University of Arizona’s microbiology department demonstrates that contaminated washing machines can transfer pathogens between loads, creating particular concerns for:

“Many people assume washing automatically sanitizes,” Dr. Martinez observes. “In reality, contaminated machines operating at low temperatures essentially redistribute bacteria across all laundry items—potentially spreading pathogens rather than eliminating them.”

Water and Energy Efficiency

Mineral scale and residue buildup forces machines to work harder:

Proper maintenance optimizes resource use, reducing both utility costs and environmental impact.

Chemical Safety and Alternatives

For households preferring minimal chemical exposure:

Natural Maintenance Protocol:

This approach achieves 80-90% effectiveness of commercial cleaners while eliminating harsh chemical exposure.

Conclusion: Engineering Hygiene Into Daily Routines

Effective washing machine maintenance transcends sporadic deep-cleaning sessions to embrace systematic practices integrated into household routines. By understanding microbial colonization patterns, respecting machine-specific vulnerabilities, and implementing evidence-based protocols, you transform your washing machine from a potential contamination source into a reliably hygienic appliance that protects household health while maximizing operational lifespan.

“The most successful maintenance programs become invisible through their integration into daily habits,” Dr. Martinez reflects. “When post-wash door-opening and gasket-wiping become as automatic as starting the wash cycle itself, contamination never gains the foothold that requires intensive intervention.”

The investment in understanding these principles—recognizing contamination mechanisms, matching cleaning chemistry to deposit types, and prioritizing preventative over reactive approaches—yields returns measured in years of reliable service, consistently fresh laundry, and the peace of mind that comes from knowing your cleaning appliance is genuinely clean.

References and Further Learning

Note: This article provides educational information based on microbiological research and appliance engineering principles. Always consult your washing machine’s owner manual for manufacturer-specific recommendations. Individual maintenance needs vary based on machine type, water quality, and usage patterns.

Read more: Simple, effective steps to make your steam iron work like new again!